The idea is to build a large CNC machine from mostly using things you find in a typical hardware store.

Original idea

- Threaded rods and nuts for driving

- Using plywood because it is easy to work with.

- Rails from aluminum angle

- Driving it with arduino

TODO

- Belt drive would be better for a large machine like that. Check out prices and how it affects presicion. If we continue to use threaded rods, we need stronger ones (New bearings other parts are needed too). Looking into prices and order parts.

- Build a new supporting structure

- Connecting motors to drivers needs proper connectors. What kind would be best?

Photos

All photos https://ipfs.io/ipfs/QmY3AjFxtYKWYjVaGSTjHeL1EAej5zLZuoS6SjeU2suz74

Design

Resources

Shop

Part list

Arduino CNC Shield V3.00

https://blog.protoneer.co.nz/arduino-cnc-shield/

Guide: https://blog.protoneer.co.nz/arduino-cnc-shield-v3-00-assembly-guide/#4THAXIS https://www.zyltech.com/arduino-cnc-shield-instructions/

Drivers

DRV8825

https://www.amazon.de/gp/product/B073VK4YN7/ref=ppx_yo_dt_b_asin_image_o03_s01?ie=UTF8&psc=1 UEETEK 5 x DRV8825 Stepper Motor Driver Module 4-Layer with Mini Heat Sink For 3D Printer The driver https://www.pololu.com/product/2133

Motors

23HS2430

http://www.datasheetcafe.com/23hs2430-pdf-datasheet-28557/

Old Notes

https://diymachining.com/grbl-feed-rate/ https://en.wikipedia.org/wiki/G-code https://www.pololu.com/product/2133

Using “Clone X-Axist to the 4th stepper” jumber configuration No microstepping jumpers added (the ones under the drivers). Using full steps. End stop jumper doesn’t exist in this version

Connect to arduino with serial terminal

$$ for list $0=10 (step pulse, usec) $1=25 (step idle delay, msec) $2=0 (step port invert mask:00000000) $3=0 (dir port invert mask:00000000) $4=0 (step enable invert, bool) $5=0 (limit pins invert, bool) $6=0 (probe pin invert, bool) $10=3 (status report mask:00000011) $11=0.010 (junction deviation, mm) $12=0.002 (arc tolerance, mm) $13=0 (report inches, bool) $20=0 (soft limits, bool) $21=0 (hard limits, bool) $22=0 (homing cycle, bool) $23=0 (homing dir invert mask:00000000) $24=25.000 (homing feed, mm/min) $25=500.000 (homing seek, mm/min) $26=250 (homing debounce, msec) $27=1.000 (homing pull-off, mm) $100=200.000 (x, step/mm) $101=250.000 (y, step/mm) $102=250.000 (z, step/mm) $110=120.000 (x max rate, mm/min) $111=500.000 (y max rate, mm/min) $112=500.000 (z max rate, mm/min) $120=60.000 (x accel, mm/sec^2) $121=10.000 (y accel, mm/sec^2) $122=10.000 (z accel, mm/sec^2) $130=200.000 (x max travel, mm) $131=200.000 (y max travel, mm) $132=200.000 (z max travel, mm)

G21 : millimeters

$100=200 $110=120

G00 X1 G00 X10

Progress

Rebuild 2024

new base

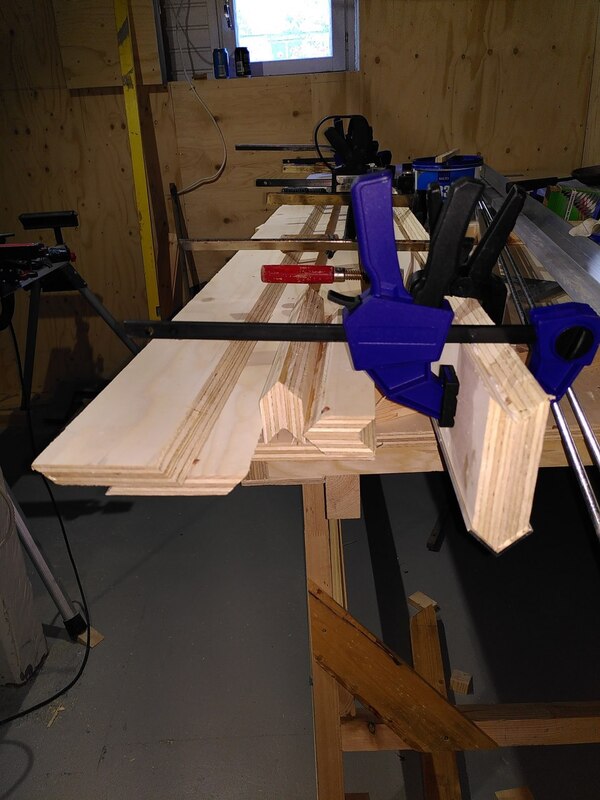

Putting it together

Building rails

https://ipfs.io/ipfs/QmQiiXmcppkZbiBLBqpeB9PksBaoErcm52GkbSRZxGVpDi?filename=VID_20200706_172613.mp4

First drawing

https://ipfs.io/ipfs/QmXixdowuzNy7f6NH2Pto9GHmj5UZyoiANJx8qEvcNDAsX?filename=KotoCNC-lq.mp4